The TM series is a highly durable semi-vortex pump constructed of titanium and special resin. This design allows for exceptional resistance to corrosion, making it an excellent choice for handling seawater. The entire pump is made of titanium, including all of the wetted metal parts, which makes it highly suitable for various applications involving the intake, transfer, and drainage of seawater.

The TM series is ideal for pumping seawater from bilges and pits of vessels. It can also be used for supplying seawater to aquariums, as well as for circulating seawater in breeding ponds. Its exceptional durability and resistance to corrosion make it an excellent choice for these demanding applications.

| Category | Series | Discharge Bore mm | Impeller | Model | Motor Output kW | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.25 | 0.4 | 0.75 | 1.5 | 2.2 | 3.7 | |||||

| Sewage | PU | 40 - 80 | Vortex | Standard | ● | ● | ● | ● | ● | ● | ● |

| Automatic | ● | ● | ● | ● | ● | ● | ● | ||||

| Auto-alternation | ● | ● | ● | ● | ● | ● | ● | ||||

| Wastewater | PN | 40 - 80 | Vortex | Standard | ● | ● | ● | ● | ● | ● | |

| Automatic | ● | ● | ● | ● | ● | ● | |||||

| Auto-alternation | ● | ● | ● | ● | ● | ● | |||||

| Wastewater

-High Head- |

PSF | 40 - 65 | Closed | Standard | ● | ● | ● | ● | ● | ● | |

| Automatic | ● | ● | ● | ● | ● | ● | |||||

| Auto-alternation | ● | ● | ● | ● | ● | ● | |||||

| Wastewater -Horizontal- |

PLS | 50 | Vortex | Standard | ● | ● | ● | ||||

| Seawater | TM | 40 - 80 | Vortex | Standard | ● | ● | ● | ● | ● | ● | |

| Automatic | ● | ● | ● | ● | ● | ● | |||||

| Wastewater -Economic- |

OM | 32 | Vortex | Standard | ● | ||||||

| Automatic | ● | ||||||||||

• Pumping seawater from bilge and pit of vessel

• Supplying seawater to aquarium

• Circulating seawater in breeding pond

The vortex impeller is adopted in every series except for the PSF-series. Rotation of the impeller produces a whirling, centrifugal action between the impeller and the pump casing, and it moves the fluid through the pump. Being coupled with a wide pump casing, wastewater containing solid matters can be pumped out without obstruction.

| Material | Stepped Shaft | Shaft Tap |

|---|---|---|

| Titanium |  |

|

| 304 Stainless Steel |

|

|

The TOK guide rail fitting system connects the

pump to and from the piping easily just by lowering

and hoisting the pump, allowing easy maintenance

and inspection without the need to enter the sump.

Made of high-quality resin, the TOK is designed

for lightweight, small to middle sized pumps.

Rubber bellows attached to the guide hook are

inverted to the duckfoot bend when the pump

starts operating, and it seals by the pumping

pressure. This eliminates leakage at the seal

even if a lightweight pump is used in combination

with the TOK.

The TOK is available in all motor output ranges of

the PU, PN, and PSF series.

The float type automatic model has an integral control circuit and two float switches that operate at a low voltage. It operates automatically in response to the change in water levels.

This model can be identified by the suffix “A” and is availa-ble in all motor output ranges of the PU, PN, PSF, and TM series.

The cylindrical float type automatic model is available only for the OM-series. Adoption of the unique float switch has made even the automatic model very compact and enables it to be installed in a limited space. Automatic operation is possible with a simple power panel.

The auto-alternation model is used along with an automatic model. The combinational use of these two pumps enables each pump to operate alter- nately without control panel.

The auto-alternation model has three floats and can be identified by the suffix “W”. Refer to model selection for availability and model num- bers of the PU, PN, and PSF series.

| Discharge Bore mm | 40 | 50 | 80 | ||

|---|---|---|---|---|---|

| Pumping Fluid |

Type of Fluid | Seawater | |||

| Fluid Temperature | 0 to 40℃ | ||||

| Pump | Structure | Impeller | Vortex | ||

| Shaft Seal | Double Mechanical Seal (with Oil Lifter) | ||||

| Bearing | Double-shielded Ball Bearing | ||||

| Materials | Impeller | Glass-fiber Reinforced Resin | |||

| Casing | Glass-fiber Reinforced Resin | ||||

| Shaft seal | Silicon Carbide | ||||

| Motor | Type, Pole | Dry-type Submersible Induction Motor, 2-pole |

|||

| Insulation | Class E | ||||

| Phase | Single-phase (suffix "S") Three-phase |

||||

| Starting Method |

Capacitor Run (single-phase only) Direct on Line |

||||

| Protection Device (Built-in) |

Circle Thermal Protector Miniature Thermal Protector (40TM2.25S & 50TM2.4S only) |

||||

| Lubricant | Liquid Paraffin (ISO VG32) | ||||

| Materials | Frame | Titanium | |||

| Shaft | Titanium | ||||

| Cable | PVC | ||||

| Discharge Connection | Screwed Flange | ||||

| Model | 100-120V | 200-240V | Length m |

Material | ||

|---|---|---|---|---|---|---|

| Cores × mm2 |

Outer Dia. mm |

Cores × mm2 |

Outer Dia. mm |

|||

| 40TM2.25S | 3 × 1.25 | 10.1 | 3 × 1.25 | 10.1 | 5 | PVC |

| 50TM2.4S | 3 × 1.25 | 10.1 | 3 × 1.25 | 10.1 | ||

| 50TM2.75S | 3 × 2.0 | 10.9 | 3 × 1.25 | 10.1 | ||

| Model | 200-240V | 380-600V | Length m |

Material | ||

|---|---|---|---|---|---|---|

| Cores × mm2 |

Outer Dia. mm |

Cores × mm2 |

Outer Dia. mm |

|||

| 40TM2.25 | 4 × 1.25 | 11.1 | 4 × 1.25 | 11.1 | 6 | PVC |

| 50TM2.4 | 4 × 1.25 | 11.1 | 4 × 1.25 | 11.1 | ||

| 50TM2.75 | 4 × 1.25 | 11.1 | 4 × 1.25 | 11.1 | ||

| 50TM21.5 | 4 × 1.25 | 11.1 | 4 × 1.25 | 11.1 | ||

| 80TM22.2 | 4 × 2.0 | 11.8 | 4 × 1.25 | 11.1 | ||

| 80TM23.7 | 4 × 3.5 | 13.9 | 4 × 2.0 | 11.8 | ||

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method |

Solids Passage mm |

Dry Weight kg | ||

|---|---|---|---|---|---|---|---|---|

| Standard | Automatic | Standard | Auto & Auto-alternation |

|||||

| 40 | 40TM2.25S | 40TMA2.25S | 0.25 | Single | Capacitor Run | 10 | 6.7 | 7.2 |

| 40 | 40TM2.25 | 40TMA2.25 | 0.25 | Three | D.O.L. | 10 | 5.7 | 6.2 |

| 50 | 50TM2.4S | 50TMA2.4S | 0.4 | Single | Capacitor Run | 10 | 6.7 | 7.2 |

| 50 | 50TM2.4 | 50TMA2.4 | 0.4 | Three | D.O.L. | 10 | 6.6 | 7.1 |

| 50 | 50TM2.75S | 50TMA2.75S | 0.75 | Single | Capacitor Run | 10 | 8.6 | 9.1 |

| 50 | 50TM2.75 | 50TMA2.75 | 0.75 | Three | D.O.L. | 10 | 7.8 | 8.4 |

| 50 | 50TM21.5 | 50TMA21.5 | 1.5 | Three | D.O.L. | 20 | 14.9 | 15.6 |

| 80 | 80TM22.2 | 80TMA22.2 | 2.2 | Three | D.O.L. | 20 | 21 | 22 |

| 80 | 80TM23.7 | 80TMA23.7 | 3.7 | Three | D.O.L. | 20 | 26 | 27 |

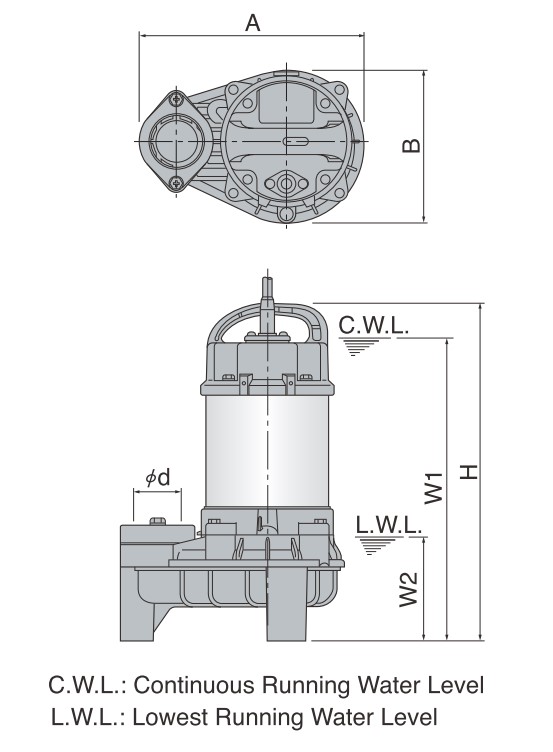

| Model | d | A | B | H | W1 | W2 |

|---|---|---|---|---|---|---|

| 40TM2.25S | 40 | 236 | 162 | 360 | 325 | 110 |

| 40TM2.25 | 40 | 236 | 162 | 349 | 310 | 110 |

| 50TM2.4S | 50 | 236 | 162 | 360 | 325 | 110 |

| 50TM2.4 | 50 | 236 | 162 | 360 | 325 | 110 |

| 50TM2.75S | 50 | 236 | 162 | 380 | 345 | 110 |

| 50TM2.75 | 50 | 236 | 162 | 374 | 335 | 110 |

| 50TM21.5 | 50 | 295 | 196 | 435 | 390 | 110 |

| 80TM22.2 | 80 | 311 | 212 | 559 | 500 | 130 |

| 80TM23.7 | 80 | 311 | 212 | 594 | 535 | 130 |