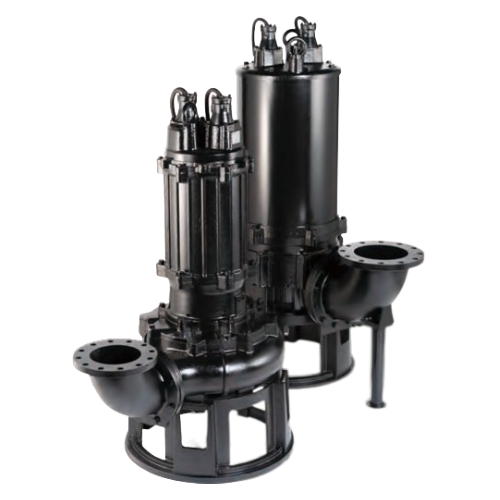

Tsurumi BZ series pumps are heavy-duty, submersible sewage and wastewater pumps that are designed with a shrouded single/two-channel impeller and wide passages of over 3

inches (76.2 mm) in diameter to minimize trouble due to clogged solids. In addition, as mid to large sized pumps with 22 – 75 kW of drive power, they raise the already high pump efficiency standard of predecessor sewage and wastewater pumps of the Tsurumi brand with even better energy efficiency.

The BZ series offers a wide line up of discharge bores ranging from 80 – 350 mm and motor outputs of 1.5 – 75 kW. Moreover, the pumps can be used with Tsurumi’s guide rail fitting device that facilitates installation and maintenance. The BZ series pumps come packed with a number of original technologies developed and honed over years of service including an anti-wicking cable, motor protector, dual inside mechanical seals with silicon carbide faces and Oil Lifter.

Highly reliable and durable, Tsurumi BZ-series pumps are designed and built for sound quality and continuous duty that can help you keep your

systems — whether for wastewater drainage, pumping or flood control — running stably and greatly reduce your maintenance costs. As an option,

the pumps can be adapted for seawater, high temperature liquids or other special application, paving the way for their use at shipyardsand power

plants for water intake and discharge.

★ : Single/Three-phase model can be selected in the same motor output.

☆ : Single-phase model only.

● : High head type model only.

| Motor Output (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3" 80mm | |||||||||||||

| 4" 100mm | ★ | ||||||||||||

| 8" 200mm | |||||||||||||

| 10" 250mm | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| 12" 300mm | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| 14" 350mm | ☆ | ☆ | ☆ | ☆ | ☆ | ☆ |

The guide rail fitting system connects the pump to and from the piping easily just by lowering and hoisting the pump, allowing easy maintenance and inspection without the need to enter the sump.

The TOS/TO is the guide rail fitting system made of cast iron and is compatible with cast iron pumps.

Accessories

• Duckfoot Bend

• Guide Support

• Guide Hook

• Lifting Chain 5m

• JIS 10kg/cm 2 Flange

(TOS set only, excluding TOS200B422)

Tsurumi offers two types of float switches (liquid level sensors). A micro-switch is incorporated in both types.

Model MC-2 is a heavy-duty type float switch with a shock absorber.

Having equipped with a high grade micro switch, the MC-2 assures trouble-free operation in the liquid containing much suspended solids and floating scum. Either of the two contacts, normally-open or normally-close, can be selected as required.

In seawater, a material’s resistance to corrosion can be seen clearly. When metals with different potentials are brought into contact in seawater, only the metal of lower potential corrodes. As the difference in potential increases, the metal of lower potential corrodes faster. As an option, Tsurumi can supply pumps with parts made of higher electric potential metal as the sacrificial anode.

Tsurumi’s submersible pumps are applicable to high temperature liquids of up to 80°C. Pumps of the standard specification can discharge liquids of up to 40°C. However, there are many fields that need to discharge higher temperature liquids, e.g., discharging industrial water from a power plant or ironworks, or discharging hot spring water from a mine in a volcanic zone.

The dry pit pumps can be installed indoors and outside of tanks, and still deliver the performance of conventional submersible pumps. Daily inspection and maintenance are easy, because the pump body is installed outside of tanks. These pumps have been developed with Tsurumi-original specifications, aiming for stable operation and reduction in maintenance labor.

1.Anti-wicking Cable Entry

Prevents water incursion due to capillary action should the cable sheath be damaged or the end of cable submerged. Also prevents moist air from infiltrating the motor housing and condensation from forming inside the housing due to temperature differences between the housing and outside air.

2.Air Release Valve

Fitted on the water jacket or the pump casing to prevent the air lock. When air flows through the valve, the ball stays at the bottom, but when the pumped water starts to flow, the ball closes the outlet because of its buoyancy.

3.Motor Protector

Circle Thermal Protector (7.5kW and below)

Directly cuts the motor circuit if excessive heat builds up or overcurrent occurs in the motor.

Miniature Thermal Protectors (11kW and above)

React to excessive heat caused by dry-running. The bimetal strip opens to cause the control panel to shut the power supply.

4.Water Jacket (150B475 only)

The pump is equipped with a water jacket, around the motor frame. A portion of the pumped liquid is allowed to flow into the water jacket to cool the motor. This design feature permits the unit to operate at low water levels for extended periods of time.

5.Dual Inside Mechanical Seals with Silicon Carbide Faces

Isolated in the oil chamber where a clean, non-corrosive and abrasion-free lubricating environment is maintained. Compared with the water-cooled outside mechanical seal, it reduces the risk of failure caused by dry-heating and adhering matter. The silicon carbide provides 5 times higher corrosion, wear and heat resistance than the tungsten carbide. Rubber parts of the upper and lower fixing rings are made of NBR or FPM (FKM), which provides higher resistance to heat and chemical

6.Oil Lifter

Provides lubrication and cooling of the seal faces down to 1/3 of normal oil level, thus maintaining a stable shaft sealing effect and prolonging seal life longer. The Oil Lifter is Tsurumi original design.

7.Leakage Sensor (22kW and above)

Detects flooding into the oil chamber that may occur in a worst case scenario. When flooding is detected, signals are sent to operate the indicator lamps through the external control panel.

8.Seal Pressure Relief Port (22kW and above)

Protects the mechanical seal from pump pressure. It also protects the seal face by discharging wear particles.

9.Back Pull-out Design (3.7kW and below, and 15kW and above)

Enables the motor to be separated from the pump unit with the impeller attached, by removing the bolts between the oil casing and the pump casing. This design facilitates maintenance and inspection of the principal parts of the pump.

Shrouded Channel Impeller

with Wide Passages to Prevent Clogging

– Over 3 Inches Passage –

BZ-series pumps come with wide passages of over 3 inches (76.2mm) in diameter — the largest being 90mm across — to minimize trouble due to clogged solids and fibrous matter. They adopt a shrouded single/two-channel impeller.

The BZ-series is a submersible sewage and wastewater pumps that is designed with a shrouded single/two-channel impeller and wide passages of over 3 inches (76.2 mm) in diameter to minimize trouble due to clogged solids. In addition, as mid to large sized pumps with 22 – 75 kW of drive power, they raise the already high pump efficiency standard of predecessor sewage and wastewater pumps of the Tsurumi brand with even better energy efficiency.

Discharge Bore: 80 • 100 • 200mm

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method |

Solids Passage mm |

Dimensions L x W x H 50/60Hz mm |

Dry Weight*2 kg |

Cable Length m |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

||||||

| 80 | 80BZ41.5 | TOS80BZ41.5 | 1.5 | Three | D.O.L. | 80 | 523 x 273 x 631 | 697 x 273 x 646 | 78 | 74 | 6 |

| 100 | 100BZ42.2 | TOS100BZ42.2 | 2.2 | D.O.L. | 80 | 551 x 273 x 631 | 709 x 273 x 646 | 80 | 74 | 6 | |

| 100BZ43.7 | TOS100BZ43.7 | 3.7 | D.O.L. | 80 | 585 x 289 x 681 | 743 x 289 x 696 | 100 | 94 | 6 | ||

| 100BZ45.5 | TOS100BZ45.5 | 5.5 | D.O.L. | 80 | 716 x 421 x 924 | 935 x 406 x 914 | 168 | 161 | 8 | ||

| 100BZ47.5 | TOS100BZ47.5 | 7.5 | D.O.L. | 80 | 716 x 421 x 945 | 935 x 406 x 935 | 179 | 172 | 8 | ||

| 100BZ411 | TOS100BZ411 | 11 | Star-Delta | 80 | 727 x 431 x 1023 | 946 x 428 x 1016 | 214 | 207 | 8 | ||

| 100BZ411H (50Hz) |

TOS100BZ411H (50Hz) |

11 | Star-Delta | 80 | 727 x 431 x 1023 | 946 x 428 x 1016 | 214 | 207 | 8 | ||

| 100BZ415 | TOS100BZ415 | 15 | Star-Delta | 80 | 845 x 526 x 1160/ 770 x 444 x 1093 |

1044 x 494 x1074/ 989 x 444 x 1081 |

308 | 293 | 8 | ||

| 200 | 200BZ622 | TQ200BZ622 | 22 | Star-Delta | 76.2 | 1208 x 760 x 1584 | 1459 x 660 x 1494 | 760 | 710 | 10 | |

| 200BZ430 | TO200BZ430 | 30 | Star-Delta | 76.2 | 1208 x 760 x 1504 | 1459 x 660 x 1409 | 780 | 730 | 10 | ||

| 200BZ437 | TQ200BZ437 | 37 | Star-Delta | 76.2 | 1208 x 760 x 1577 | 1459 x 660 x 1482 | 830 | 780 | 10 | ||

| 200BZ445 | TO200BZ445 | 45 | Star-Delta | 76.2 | 1208 x 760 x 1584 | 1459 x 660 x 1494 | 840 | 790 | 10 | ||

| 200BZ455 | TO200BZ455 | 55 | Star-Delta | 76.2 | 1208 x 760 x 1736 | 1461 x 660 x 1646 | 1340 | 1290 | 10 | ||

| 200BZ475 | T0200BZ475 | 75 | Star-Delta | 76.2 | 1208 x 760 x 1736 | 1461 x 660 x 1646 | 1340 | 1290 | 10 | ||

* 1 Refer to page 11 for dimension symbol positions.

* 2 All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

Discharge Bore: 250mm

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method |

Solids Passage 50/60Hz mm |

Dimensions L x W x H*1 mm |

Dry Weight*2 kg |

Cable Length m |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

||||||

| 250 | 250BZ622 | TO250BZ622 | 22 | Three | Star-Delta | 90/80 | 1235 x 724 x 1650 | 1486 x 616 x 1514 | 810 | 760 | 10 |

| 250BZ430 | TO250BZ430 | 30 | Star-Delta | 80/79 | 1235 x 724 x 1570 | 1486 x 616 x 1434 | 830 | 780 | 10 | ||

| 250BZ437 | TO250BZ437 | 37 | Star-Delta | 80/79 | 1235 x 724 x 1643 | 1486 x 616 x 1507 | 880 | 830 | 10 | ||

| 250BZ445 | TO250BZ445 | 45 | Star-Delta | 80/79 | 1235 x 724 x 1650 | 1486 x 616 x 1514 | 890 | 840 | 10 | ||

| 250BZ455 | TO250BZ455 | 55 | Star-Delta | 90/80 | 1235 x 724 x 1802 | 1519 x 636 x 1666 | 1390 | 1290 | 10 | ||

| 250BZ475 | TO250BZ475 | 75 | Star-Delta | 90/80 | 1235 x 724 x 1802 | 1519 x 636 x 1666 | 1390 | 1290 | 10 | ||

| 250 -High Head |

250BZ622H | TO250BZ622H | 22 | Star-Delta | 76.2 | 1313 x 760 x 1584 | 1577 x 660 x 1467 | 760 | 710 | 10 | |

| 250BZ430H | TO250BZ430H | 30 | Star-Delta | 76.2 | 1313 x 760 x 1504 | 1577 x 660 x 1387 | 780 | 730 | 10 | ||

| 250BZ437H | TO250BZ437H | 37 | Star-Delta | 76.2 | 1313 x 760 x 1577 | 1577 x 660 x 1460 | 830 | 780 | 10 | ||

| 250BZ445H | TO250BZ445H | 45 | Star-Delta | 76.2 | 1313 x 760 x 1584 | 1577 x 660 x 1467 | 840 | 790 | 10 | ||

| 250BZ455H | TO250BZ455H | 55 | Star-Delta | 76.2 | 1313 x 760 x 1736 | 1579 x 660 x 1619 | 1340 | 1290 | 10 | ||

| 250BZ475H | TO250BZ475H | 75 | Star-Delta | 76.2 | 1313 x 760 x 1736 | 1579 x 660 x 1619 | 1340 | 1290 | 10 | ||

* 1 Refer to page 11 for dimension symbol positions.

* 2 All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

Discharge Bore: 300mm

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method |

Solids Passage 50/60Hz mm |

Dimensions L x W x H*1 mm |

Dry Weight*2 kg |

Cable Length m |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

||||||

| 300 | 300BZ622 | TO300BZ622 | 22 | Three | Star-Delta | 90 | 1386 x 800 x 1677 | 1674 x 658 x 1550 | 910 | 810 | 10 |

| 300BZ630 | TO300BZ630 | 30 | Star-Delta | 90 | 1386 x 800 x 1677 | 1674 x 658 x 1550 | 950 | 800 | 10 | ||

| 300BZ637 | TO300BZ637 | 37 | Star-Delta | 90 | 1386 x 800 x 1677 | 1674 x 658 x 1550 | 940 | 840 | 10 | ||

| 300BZ645 | TO300BZ645 | 45 | Star-Delta | 90 | 1386 x 800 x 1845 | 1691 x 680 x 1718 | 1210 | 1110 | 10 | ||

| 300BZ655 | TO300BZ655 | 55 | Star-Delta | 90 | 1386 x 800 x 1845 | 1691 x 680 x 1718 | 1210 | 1110 | 10 | ||

| 300BZ475 | TO300BZ475 | 75 | Star-Delta | 90 | 1386 x 800 x 1829 | 1674 x 680 x 1702 | 1240 | 1140 | 10 | ||

| 300 -High Head |

300BZ622H | TO300BZ622H | 22 | Star-Delta | 90/80 | 1288 x 724 x 1650 | 1580 x 616 x 1537 | 810 | 760 | 10 | |

| 300BZ430H | TO300BZ430H | 30 | Star-Delta | 80/79 | 1288 x 724 x 1570 | 1580 x 616 x 1457 | 830 | 780 | 10 | ||

| 300BZ437H | TO300BZ437H | 37 | Star-Delta | 80/79 | 1288 x 724 x 1643 | 1580 x 616 x 1530 | 880 | 830 | 10 | ||

| 300BZ445H | TO300BZ445H | 45 | Star-Delta | 80/79 | 1288 x 724 x 1650 | 1580 x 616 x 1537 | 890 | 840 | 10 | ||

| 300BZ455H | TO300BZ455H | 55 | Star-Delta | 90/80 | 1288 x 724 x 1802 | 1613 x 616 x 1689 | 1390 | 1290 | 10 | ||

| 300BZ475H | TO300BZ475H | 75 | Star-Delta | 90/80 | 1288 x 724 x 1802 | 1613 x 616 x 1689 | 1390 | 1290 | 10 | ||

* 1 Refer to page 11 for dimension symbol positions.

* 2 All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

Discharge Bore: 350mm

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method |

Solids Passage 50/60Hz mm |

Dimensions L x W x H mm |

Dry Weight* kg |

Cable Length m |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

||||||

| 350 -High Head- |

350BZ622H | TO350BZ622H | 22 | Three | Star-Delta | 90 | 1508 x 800 x 1677 | 1749 x 658 x 1595 | 910 | 810 | 10 |

| 350BZ630H | TO350BZ630H | 30 | Star-Delta | 90 | 1508 x 800 x 1677 | 1749 x 658 x 1595 | 950 | 800 | 10 | ||

| 350BZ637H | TO350BZ637H | 37 | Star-Delta | 90 | 1508 x 800 x 1677 | 1749 x 658 x 1595 | 940 | 840 | 10 | ||

| 350BZ645H | TO350BZ645H | 45 | Star-Delta | 90 | 1508 x 800 x 1845 | 1749 x 680 x 1763 | 1210 | 1110 | 10 | ||

| 350BZ655H | TO350BZ655H | 55 | Star-Delta | 90 | 1508 x 800 x 1845 | 1749 x 680 x 1763 | 1210 | 1110 | 10 | ||

| 350BZ475H | TO350BZ475H | 75 | Star-Delta | 90 | 1508 x 800 x 1829 | 1749 x 680 x 1747 | 1240 | 1140 | 10 | ||

* All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

| #1 | BZ | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 80BZ41.5 | 100BZ42.2 | 100BZ43.7 | 100BZ45.5 | 100BZ47.5 | 100BZ411 | 1008741H (50Hz) |

100BZ415 | ||

| PUMP | Discharge Bore mm | 80 | 100 | ||||||

| Discharge Connection | Threaded JIS 10kg/cm 2 Flange | ||||||||

| Solids Passage 5060Hz mm | 80 | ||||||||

| Impeller | Shrouded Single-channel | ||||||||

| Radial Gap | Axial Gap | ||||||||

| Gray Cast Iron | |||||||||

| Suction Cover | - | Gray Cast Iron | |||||||

| Oil Seal | Nitrile Butadiene Rubber | - | |||||||

| Casing | Gray Cast Iron | ||||||||

| Shaft Seal | Dual Inside Mechanical Seals (with Oil Lifter) | ||||||||

| Silicon Carbide | |||||||||

| Shaft Sleeve | - | ||||||||

| MOTOR | Type | Continuous-duty Rated, Dry-type Induction Motor | |||||||

| Output kW | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | ||

| Phase | Three | ||||||||

| Pole | 4 | ||||||||

| Speed (S.S.) min -1 50/60Hz |

1500/1800 | 1500/- | 1500/1800 | ||||||

| Insulation | E | F | |||||||

| Starting Method | D.O.L. | Star-Delta | |||||||

| Motor Protector (built-in) |

CTP | MTP | |||||||

| Leakage Sensor (built-in) |

- | ||||||||

| Lubricant ml | 1300 | 4200 | 4800 | 6500 | 5500 | ||||

| Turbine Oil (ISO VG32) | |||||||||

| Frame | Gray Cast Iron | ||||||||

| Outor Cover | - | ||||||||

| Shaft | 420 Stainless Steel | ||||||||

| Power Cable m | P6 | 8 | |||||||

| PVC | Chloroprene Rubber | ||||||||

| Dry Weight* | Free Standing kg | 78 | 80 | 100 | 168 | 179 | 214 | 308 | |

| Guide Rail Fitting kg | 74 | 94 | 161 | 172 | 207 | 293 | |||

* All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

| #2 | BZ | ||||||

|---|---|---|---|---|---|---|---|

| 200BZ622 250BZ622H |

200BZ430 250BZ430H |

200BZ437 250BZ437H |

200BZ445 250BZ445H |

200BZ455 250BZ455H |

200BZ475 250BZ475H |

||

| PUMP | Discharge Bore mm | 200 250 |

|||||

| Discharge Connection | JIS 10kg/cm 2 Flange | ||||||

| Solids Passage 5060Hz mm | 76.2 | ||||||

| Impeller | Shrouded Two-channel | ||||||

| Radial Gap | |||||||

| Gray Cast Iron | |||||||

| Suction Cover | Gray Cast Iron | ||||||

| Oil Seal | Nitrile Butadiene Rubber | ||||||

| Casing | Gray Cast Iron | ||||||

| Shaft Seal | Dual Inside Mechanical Seals (with Oil Lifter) | ||||||

| Silicon Carbide | |||||||

| Shaft Sleeve | 304 Stainless Steel | 403 Stainless Steel | |||||

| MOTOR | Type | Continuous-duty Rated, Dry-type Induction Motor | |||||

| Output kW | 22 | 30 | 37 | 45 | 55 | 75 | |

| Phase | Three | ||||||

| Pole | 6 | 4 | |||||

| Speed (S.S.) min -1 50/60Hz |

1000/1200 | 1500/1800 | |||||

| Insulation | F | ||||||

| Starting Method | Star-Delta | ||||||

| Motor Protector (built-in) |

MTP | ||||||

| Leakage Sensor (built-in) |

Electrode | ||||||

| Lubricant ml | 9500 | 9400 | |||||

| Turbine Oil (ISO VG32) | |||||||

| Frame | Gray Cast Iron | ||||||

| Outor Cover | - | Rolled Steel | |||||

| Shaft | 420 Stainless Steel | ||||||

| Power Cable m | 10 | ||||||

| Chloroprene Rubber | |||||||

| Dry Weight* | Free Standing kg | 760 | 780 | 830 | 840 | 1340 | |

| Guide Rail Fitting kg | 710 | 730 | 780 | 790 | 1290 | ||

* All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend

| #3 | BZ | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 250BZ622 300BZ622H |

250BZ430 300BZ430H |

250BZ437 300BZ437H |

250BZ445 300BZ445H |

250BZ455 300BZ455H |

H 250BZ475 300BZ475H |

300BZ622 350BZ622H |

300BZ630 350BZ630H |

H 300BZ637 350BZ637H |

300BZ645 350BZ645H |

300BZ655 350BZ655H |

300BZ475 350BZ475H |

||

| PUMP | Discharge Bore mm | 250 300 |

300 350 |

||||||||||

| Discharge Connection | JIS 10kg/cm 2 Flange | ||||||||||||

| Solids Passage 5060Hz mm | 90/80 | 80/79 | 90/80 | 90 | |||||||||

| Impeller | Shrouded Two-channel | ||||||||||||

| Radial Gap | |||||||||||||

| Gray Cast Iron | |||||||||||||

| Suction Cover | Gray Cast Iron | ||||||||||||

| Oil Seal | Nitrile Butadiene Rubber | ||||||||||||

| Casing | Gray Cast Iron | ||||||||||||

| Shaft Seal | Dual Inside Mechanical Seals (with Oil Lifter) | ||||||||||||

| Silicon Carbide | |||||||||||||

| Shaft Sleeve | 304 Stainless Steel | 403 Stainless Steel | 304 Stainless Steel | 403 Stainless Steel | |||||||||

| MOTOR | Type | Continuous-duty Rated, Dry-type Induction Motor | |||||||||||

| Output kW | 22 | 30 | 37 | 45 | 55 | 75 | 22 | 30 | 37 | 45 | 55 | 75 | |

| Phase | Three | ||||||||||||

| Pole | 6 | 4 | 6 | 4 | |||||||||

| Speed (S.S.) min -1 50/60Hz |

1000/1200 | 1500/1800 | 1000/1200 | 1500/1800 | |||||||||

| Insulation | F | ||||||||||||

| Starting Method | Star-Delta | ||||||||||||

| Motor Protector (built-in) |

MTP | ||||||||||||

| Leakage Sensor (built-in) |

Electrode | ||||||||||||

| Lubricant ml | 9500 | 9400 | 9500 | 11000 | 13000 | 9400 | |||||||

| Turbine Oil (ISO VG32) | |||||||||||||

| Frame | Gray Cast Iron | ||||||||||||

| Outor Cover | - | Rolled Steel | - | Rolled Steel | |||||||||

| Shaft | 420 Stainless Steel | ||||||||||||

| Power Cable m | 10 | ||||||||||||

| Chloroprene Rubber | |||||||||||||

| Dry Weight* | Free Standing kg | 810 | 830 | 880 | 890 | 190 | 910 | 950 | 940 | 1210 | 1240 | ||

| Guide Rail Fitting kg | 760 | 780 | 830 | 840 | 1290 | 810 | 800 | 840 | 1110 | 1140 | |||

* All weights excluding cable

Weights of guide rail fitting excluding duckfoot bend