Submersible Slurry Pumps GPN Series is a submersible high power, heavy-duty slurry pump incorporating an agitator to suspend solids enabling the pump to handle high concentration slurries. Being equipped with high-chromium cast iron wear parts, the pump delivers outstanding durability. The suction plate is adjustable enabling the pump to maintain the original performance*. The GPN utilizes a cooling water jacket to allow the pump to operate at low water levels for extended period of time without the fear of overheating.

The GPN-series is a submersible three-phase high power and extra heavy-duty slurry pump driven by a 4-pole or 6-pole motor. It is equipped with a high-chromium cast iron agitator that assists smooth suction of the settled matters. The other wear parts such as the impeller and the suction plate are also made of high-chromium cast iron for extra durability. The side discharge, spiral design allows smoother passage of the sucked solid matters. The motor is cooled by a water jacket that assures efficient motor cooling even when it operates with its motor exposed to air.

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Starting Method | Solids Passage mm |

Dimensions L x H mm |

Dry Weight*2 kg |

Cable Length m |

|---|---|---|---|---|---|---|---|---|

| 80 | GPN35.5 | 5.5 | Three | D.O.L.*1 | 30 | 487 x 796 | 145 | 8 |

| 100 | GPN411 | 11 | D.O.L.*1 | 30 | 617 x 879 | 217 | 8 | |

| 100 | GPN415 | 15 | D.O.L.*1 | 30 | 617 x 879 | 220 | 10 | |

| 100 | GPN422 | 22 | D.O.L.*1 | 30 | 725 x 1102 | 415 | 10 | |

| 150 | GPN622 | 22 | D.O.L.*1 | 30 | 725 x 1102 | 415 | 10 | |

| 200 | GPN837 | 37 | Star-Delta | 46 | 1015 x 1606 | 800 | 10 |

The side discharge, spiral design allows smoother passage of the sucked solid matters. The motor is cooled by a water jacket assuring efficient motor cooling even when the pump operates with its motor exposed to air.

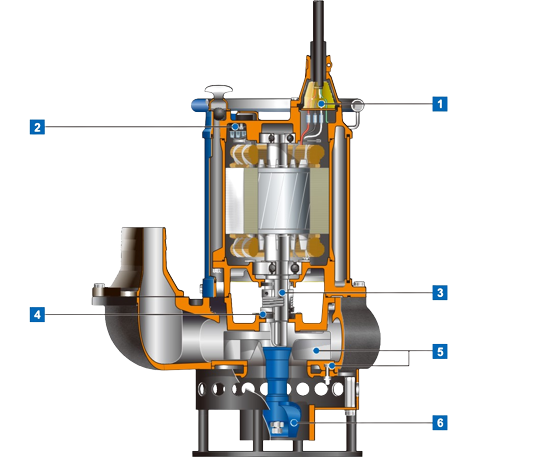

1.Anti-wicking Cable Entry

Prevents water incursion due to capillary wicking should the power cable be damaged or the end submerged.

2.Motor Protector

Circle Thermal Protector (15kW and below)

Directly cuts the motor circuit if excessive heat builds up or overcurrent occurs in the motor.

Miniature Thermal Protectors (22kW and above)

React to excessive heat caused by dry-running. The bimetal strip opens to cause the control panel to shut the power supply.

3.Chromium Molybdenum Shaft

Made of SCM435 (JIS), chromium molybdenum steel (tensile strength 930 N/mm2 and over). It has the superior performance against a shock given at the instant of sucking hard foreign matters.

4.Inside Mechanical Seal with Silicon Carbide Faces (15kW and below)

Dual Inside Mechanical Seals with Silicon Carbide Faces (22kW and above)

Isolated in the oil chamber where a clean, non-corrosive and abrasion-free lubricating environment is maintained. Compared with the water-cooled outside mechanical seal, it reduces the risk of failure caused by dry-heating and adhering matter. The silicon carbide provides 5 times higher corrosion, wear and heat resistance than the tungsten carbide.

*GPN422/622/837 have the Oil Lifter forcibly lubricating and cooling the mechanical seal.

5. High-chromium Cast Iron Impeller & Suction Plate

Made of high-chromium cast iron ensuring highest durability. Even if the performance drops due to wearing outof the impeller and/or suction plate, it can be improved by simply replacing the suction plate.

*GPN422/622/837 have an adjustable suction plate.

6. Agitating Mechanism

Consists of a shaft-mounted agitator and a dedicated strainer. The agitator made of high-chromium cast iron resists wear caused by abrasive particles, and it suspends solids to assist in pumping sediments in combination with the strainer.

| GPN | |||||||

|---|---|---|---|---|---|---|---|

| GPN35.5 | GPN411 | GPN415 | GPN422 | GPN622 | GPN837 | ||

| PUMP | Discharge Bore mm | 80 | 100 | 150 | 200 | ||

| Discharge Connection | Hose Coupling | ||||||

| Solids Passage mm | 30 | 46 | |||||

| Impeller | Semi-open | ||||||

| High-chromium Cast Iron | |||||||

| Suction Cover | Gray Cast Iron | ||||||

| Suction Plate | High-chromium Cast Iron | ||||||

| Oil Seal | Nitrile Butadiene Rubber | ||||||

| Casing | Gray Cast Iron | ||||||

| Shaft Seal | Inside Mechanical Seal (without Oil Lifter) | Dual Inside Mechanical Seals (with Oil Lifter) | |||||

| Silicon Carbide | |||||||

| Shaft Sleeve | 403 Stainless Steel | ||||||

| Agitator | High-chromium Cast Iron | ||||||

| MOTOR | Type | Continuous-duty Rated, Dry-type Induction Motor | |||||

| Output kW | 5.5 | 11 | 15 | 22 | 37 | ||

| Phase | Three | ||||||

| Pole | 4 | 6 | |||||

| Insulation | E | B | F | ||||

| Starting Method | D.O.L.*2 | Star-Delta | |||||

| Motor Protector (built-in) | CTP | MTP | |||||

| Leakage Sensor (built-in) | - | Electrode | |||||

| ml | 1100 | 2500 | 3600 | 9200 | |||

| Lubricant | |||||||

| Turbine Oil (ISO VG32) | |||||||

| Frame | Gray Cast Iron | ||||||

| Shaft | Chromium Molybdenum Steel | ||||||

| ml | 8 | 10 | |||||

| Cable | Chloroprene Rubber | ||||||

| Dry Weight*1 kg | 145 | 217 | 220 | 415 | 800 | ||