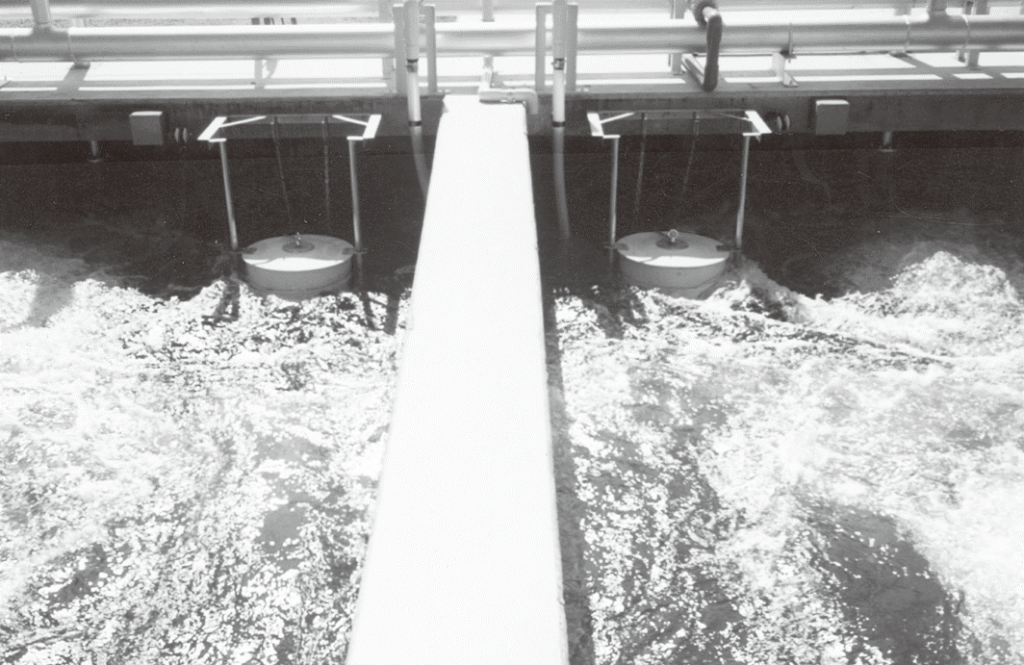

FLOATING DECANTERS FHP SERIES is a floating decanter designed for discharging supernatant liquid in SBR. It consists of a submersible pump, sludge sensor, and a float.

The sludge sensor is a monitoring device that prevents unexpected inflow of sludge or other sediment and helps the pump solely discharge supernatant liquid. When the pump is not in operation, a check ball incorporated in the intake closes the suction opening by buoyancy, thus preventing the inflow of floating sludge into the suction casing.

| Discharge Bore mm |

Model | Motor Output kW |

Phase | Speed (S.S.) min-1 |

Starting Method | Dry Weight *kg |

Cable Length m |

|---|---|---|---|---|---|---|---|

| 40 | FHP3-3 | 0.25 | Single | 3000/3600 | Capacitor Start | 29 | 6 |

| 40 | FHP3-3T | 0.25 | Three | 3000/3600 | D.O.L. | 27 | 6 |

| 50 | FHP2-4 | 0.4 | Single | 3000/3600 | Capacitor Start | 29 | 6 |

| 50 | FHP2-4T | 0.4 | Three | 3000/3600 | D.O.L. | 27 | 6 |

| 50 | FHP4-8T | 0.75 | Three | 3000/3600 | D.O.L. | 28 | 6 |

| 80 | FHP2-15T | 1.5 | Three | 3000/3600 | D.O.L. | 60 | 6 |

| Major Components & Specifications | |||||

|---|---|---|---|---|---|

| Discharge Bore mm | 40 | 50 | 80 | ||

| Pumping Fluid | Type of Fluid | Treated Water | |||

| Fluid Temperature | 0 to 40˚C | ||||

| Pump | Structure | Impeller | Channel | ||

| Shaft Seal | Double Mechanical Seal | ||||

| Bearing | Double-shielded Ball Bearing | ||||

| Materials | Impeller | Gray Cast Iron | |||

| Casing | Gray Cast Iron | ||||

| Shaft seal | Silicon Carbide | ||||

| Float | FRP | ||||

| Motor | Type, Pole | Dry Type Submersible Induction Motor, 2-pole | |||

| Insulation | Class E | ||||

| Class F (1.5kW only) | |||||

| Phase | Single-phase | ||||

| Three-phase (suffix "T") | |||||

| Starting Method | Capacitor Start (Single-phase only) Direct on Line | ||||

| Protection Device (built-in) | Circle Thermal Protector | ||||

| Lubricant | Turbine Oil (ISO VG32) | ||||

| Materials | Frame | Gray Cast Iron | |||

| Shaft | 420 Stainless Steel | ||||

| Cable | PVC | ||||

| Discharge Connection | Hose Coupling | ||||

1.Float

The float sustains a submersible pump by buoyancy at an appropriate position.

Made of fiber reinforced plastic (FRP), the float is filled with polystyrene foam which prevents the loss of buoyancy in case the float is broken.

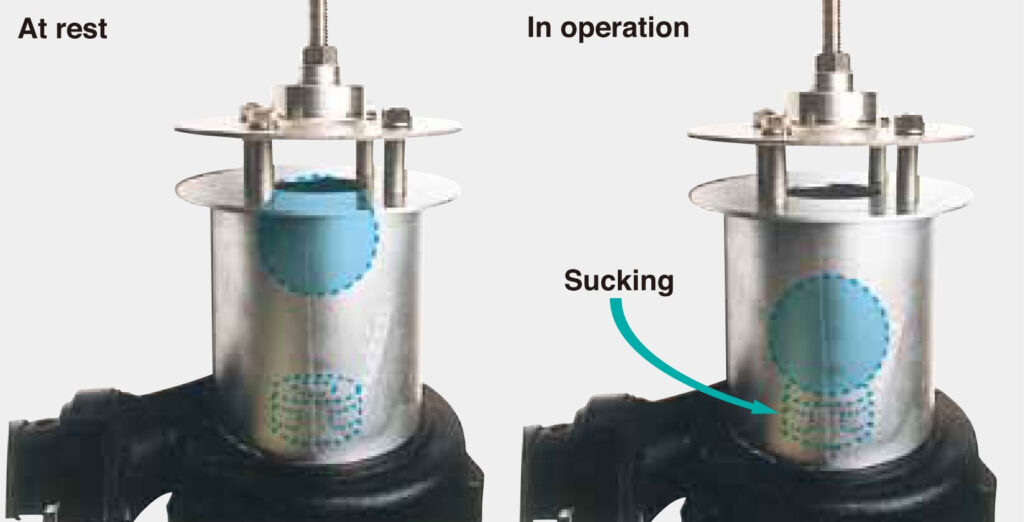

2.Intake Check Ball

A check ball incorporated in the intake closes the suction mouth by buoyancy when the pump stops operating thus preventing the inflow of floating sludge.

During operation, the ball is sucked in by the pump’s suction power to take in supernatant liquid.

3.Pumping Section

Each component, such as dual inside mechanical seal, motor protector, and anti-wicking cable entry, represents Tsurumi’s outstanding expertise.

4.Amplifier Unit Box

5.Anti-sludge Sensor

When the amount of light transmitted from an emitter via glass fibers is reduced by a certain density of sludge existing in the liquid, the sensor identifies the light amount and sends corresponding signals to the control panel to stop or operate the pump not to suck up sludge.

6.Sensor Cleaner

The sensor cleaner spouts a jet of clean water from its nozzle to wash the light emitter and receiver at fixed intervals. The pressurized water can be treated water coming from a submersible pump installed in the spray pump tank.

Recommendation;