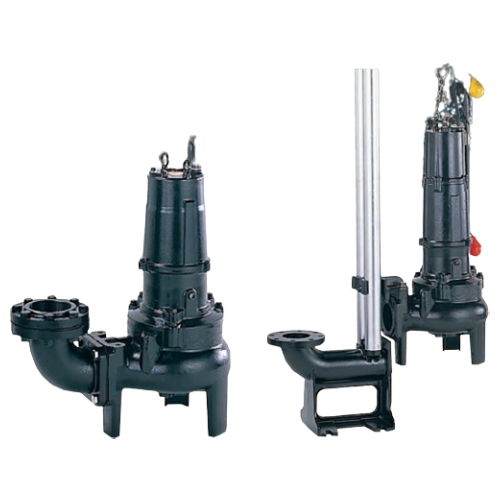

Tsurumi U Series pumps are a part of the submersible sewage pumps vortex impeller series. These pumps feature a vortex impeller that is recessed in the pump casing interior, which allows them to handle sewage with large solids without clogging or winding.

Thanks to their unique design, the Tsurumi U Series pumps are ideal for applications that require the pumping of sewage or wastewater containing large solid materials. Their ability to handle such materials without clogging or winding makes them a reliable choice for a wide range of sewage and wastewater management applications.

In addition to their robust performance, the Tsurumi U Series pumps are also designed for ease of use and maintenance. Their simple yet efficient design allows for quick and easy access to the impeller and other key components, making maintenance and repair work much more straightforward.

The guide rail fitting system connects the pump to and from the piping easily just by lowering and hoisting the pump, allowing easy maintenance and inspection without the need to enter the sump.

Pump models used in combination with the guide rail fitting system can be identified by the prefix “TOS”, “TS” and “TOK”. Refer to standard specifications for availability and model numbers.

The automatic model has an integral control circuit and two float switches that operate at a low voltage. It operates automatically in response to the change in water levels. As it has a Circle Thermal Protector (CTP) integrated into the motor to protect the motor from overload or overheating, it is not required to provide an extra motor protection circuit in the starter panel.

This model can be identified by the suffix “A”. Refer to the standard specifications for availability and model numbers.

The auto-alternation model is used along with an automatic model. The combinational use of these two pumps enables each pump to operate alternately without control panel.

The auto-alternation model has three floats and can be identified by the suffix “W”. Refer to standard specifications for availability and model numbers. It is available in the same output range of the automatic pumps.

– Operation is enabled by merely connecting the power supply.

U Series Discharge Bore: 40 • 50mm

U Series Discharge Bore: 40 • 50mm

| Curve No. | Discharge Bore mm |

Standard Model | Automatic Model | Auto-Alternation Model | |||

|---|---|---|---|---|---|---|---|

| Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | ||

| 1 | 40 | 40U2.25S | (TOK) | 40UA2.25S | (TOK) | 40UW2.25S | (TOK) |

| 40 | 40U2.25 | (TOK) | 40UA2.25 | (TOK) | 40UW2.25 | (TOK) | |

| 2 | 50 | 50U2.4S | (TOK) | 50UA2.4S | (TOK) | 50UW2.4S | (TOK) |

| 50 | 50U2.4 | (TOK) | 50UA2.4 | (TOK) | 50UW2.4 | (TOK) | |

| 3 | 50 | 50U2.75 | (TOK) | 50UA2.75 | (TOK) | 50UW2.75 | (TOK) |

| 4 | 50 | 50U21.5 | TOS50U21.5 | 50UA21.5 | TOS50UA21.5 | 50UW21.5 | TOS50UW21.5 |

* All weights excluding cable

Weights of guide rail fitting model excluding duckfoot bend

| Motor Output kW |

Phase | Speed (S.S.) 50Hz/60Hz min -1 |

Starting Method |

Solids Passage mm |

Cable Length m |

Cable Code |

Dimensions L×H mm | Dry Weight * kg | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Model | Auto&Auto-Alternation Model | Standard Model | Auto&Auto-Alternation Model | |||||||||||

| Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | |||||||

| 0.25 | Single | 3000/3600 | Split-phase | 35 | 5 | a | 241×383 | - | 241×433 | - | 14 | - | 15.5 | - |

| 0.25 | Three | 3000/3600 | D.O.L. | 35 | 6 | A | 241×383 | - | 241×433 | - | 13.5 | - | 15 | - |

| 0.4 | Single | 3000/3600 | Capacitor | 35 | 5 | a | 236×433 | - | 236×450 | - | 20 | - | 21 | - |

| 0.4 | Three | 3000/3600 | D.O.L. | 35 | 6 | A | 236×400 | - | 236×450 | - | 19.2 | - | 21 | - |

| 0.75 | Three | 3000/3600 | D.O.L. | 35 | 6 | A | 249×395 | - | 310×476 | - | 23 | - | 24 | - |

| 1.5 | Three | 3000/3600 | D.O.L. | 35 | 6 | A | 297×466 | 658×478 | 347×560 | 708×572 | 30 | 35 | 31 | 36 |

* All weights excluding cable

Weights of guide rail fitting model excluding duckfoot bend

U Series Discharge Bore: 80mm

U Series Discharge Bore: 80mm

| Curve No. |

Discharge Bore mm |

Standard Model | Automatic Model | Auto-Alternation Model | |||

|---|---|---|---|---|---|---|---|

| Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | Free Standing | Guide Rail Fitting | ||

| 1 | 80 | 80U2.75 | TOS80U2.75 | 80UA2.75 | TOS80UA2.75 | 80UW2.75 | TOS80UW2.75 |

| 2 | 80 | 80U21.5 | TOS80U21.5 | 80UA21.5 | TOS80UA21.5 | 80UW21.5 | TOS80UW21.5 |

| 3 | 80 | 80U22.2 | TOS80U22.2 | 80UA22.2 | TOS80UA22.2 | 80UW22.2 | TOS80UW22.2 |

| 4 | 80 | 80U23.7 | TOS80U23.7 | 80UA23.7 | TOS80UA23.7 | 80UW23.7 | TOS80UW23.7 |

* 1 200~240V

* 2 All weights excluding cable

Weights of guide rail fitting model excluding duckfoot bend

| Motor Output kW | Phase | Speed (S.S.) 50Hz/60Hz min -1 |

Starting Method |

Solids Passage mm |

Cable Length m |

Cable Code |

Dimensions L×H mm | Dry Weight *2 kg | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Model | Auto&Auto-Alternation Model |

Standard Model | Auto&Auto-Alternation Model |

|||||||||||

| Free Standing |

GuideRail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

Free Standing |

Guide Rail Fitting |

|||||||

| 0.75 | Three | 3000/3600 | D.O.L. | 46 | 6 | A | 383×421 | 605×531 | 444×502 | 666×612 | 29 | 24 | 30 | 26 |

| 1.5 | Three | 3000/3600 | D.O.L. | 46 | 6 | A | 420×499 | 642×609 | 469×593 | 691×703 | 40 | 36 | 41 | 37 |

| 2.2 | Three | 3000/3600 | D.O.L. | 56 | 6 | A(B*1) | 502×562 | 641×647 | 502×656 | 641×741 | 55 | 51 | 63 | 59 |

| 3.7 | Three | 3000/3600 | D.O.L. | 56 | 6 | B(C*1) | 502×565 | 641×650 | 502×629 | 641×714 | 62 | 58 | 73 | 69 |

* 1 200~240V

* 2 All weights excluding cable

Weights of guide rail fitting model excluding duckfoot bend

Single-Phase

| Code | No. of Cables |

Cores × mm2 | Outer Dia. mm |

Material |

|---|---|---|---|---|

| a | 1 | 3×1.25 | 10.1 | PVC |

Three-Phase

| Code | No. of Cables |

Cores × mm2 | Outer Dia. mm |

Material |

|---|---|---|---|---|

| A | 1 | 4×1.25 | 11.1 | PVC |

| B | 1 | 4×2.0 | 11.8 | |

| C | 1 | 4×3.5 | 13.9 |

| Code | No. of Cables |

Cores × mm 2 | Outer Dia. mm |

Material |

|---|---|---|---|---|

| D | 1 | 4×3.5 | 14.1 | Chloroprene Rubber |

| E | 1 | 4×5.5 | 16.8 | |

| F | 3 | 4×3.5 | 14.1 | Chloroprene Rubber |

| 3×3.5 | 12.9 | |||

| 2×1.25 | 9.6 | PVC |

Model MC-2 is a heavy-duty type float switch with a shock absorber.

Having equipped with a high grade micro switch, the MC-2 assures trouble-free operation in the liquid containing much suspended solids and floating scum. Either of the two contacts, normally-open or normally-close, can be selected as required.